TIG Torches & GTAW Parts

Showing 41–60 of 110 resultsSorted by popularity

Weldmark 1/8″ TIG Gas Lens Collet Body For HW-17, 18, 26 Torches

Weldmark 1/8″ TIG Gas Lens Collet Body For HW-17, 18, 26 Torches

Weldmark TIG Collet 1/8″ For HW-20, 9, 25 Torches

Weldmark TIG Collet 1/8″ For HW-20, 9, 25 Torches

Weldmark #8 Gas Lens Alumina For HW-17,18,26 Torches

Weldmark #8 Gas Lens Alumina For HW-17,18,26 Torches

Weldmark #7 Alumina Nozzle For HW-17,18,26 Torches

Weldmark #7 Alumina Nozzle For HW-17,18,26 Torches

Weldmark TIG Long Back Cap For HW-17,18,26 Tig Torches

Weldmark TIG Long Back Cap For HW-17,18,26 Tig Torches

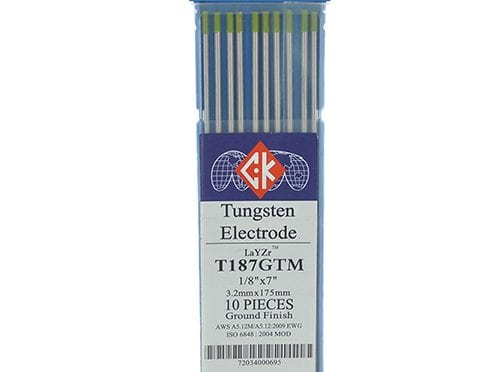

CK Worldwide Layzr Tungsten 1/8″ X 7″

CK Worldwide Layzr Tungsten 1/8″ X 7″

Tungsten Electrode 1/8” x 7” Layzr Non-Radioactive.

Best for automated or robotic applications in alternating current (a/c) or direct current (d/c) due to low voltage tolerance (changes in tip to work piece distance) using inverter or transformer based constant current power sources. Good for low-alloyed steels, Non corroding steels, aluminum alloys, magnesium alloys, titanium alloys, nickel alloys, copper alloys. Runs cooler than 2% Thoriated with longer life, low to medium amperage range. Best for low amperage starts.

- AWS A5.12 EWG

- ISO 6848

Weldmark 2% Thoriated Tungsten 1/8″ X 7″

Weldmark 2% Thoriated Tungsten 1/8″ X 7″

1/8” X 7” Ground 2% Thoriated Tungsten Electrode

Extremely long lasting and highly durable, these electrodes are a staple in DC welding applications. They are the most commonly used electrodes today and are preferred for their longevity and ease of use. Thorium increases the electron emission qualities of the electrode, which improves arc starts and allows for a higher current-carrying capacity. This electrode operates far below its melting temperature, which results in a considerably lower rate of consumption and eliminates arc wandering for greater stability. Compared with other electrodes, Thoriated electrodes deposit less tungsten into the weld puddle, so they cause less weld contamination.

These electrodes are used mainly for specialty AC welding (such as thin-gauge aluminum and material less than 0.060 inch) and DC welding, either electrode negative or straight polarity, on carbon steel, stainless steel, nickel, and titanium.

During manufacturing, thorium is evenly dispersed throughout the electrode, which helps the tungsten maintain its sharpened edge—the ideal electrode shape for welding thin steel—after grinding. Note: Thorium is radioactive; therefore, you must always follow the manufacturer’s warnings, instructions, and the Safety Data Sheet (SDS) for its use.

Weldmark TIG Collet 1/8″ For HW-17, 18, 26 Torches

Weldmark TIG Collet 1/8″ For HW-17, 18, 26 Torches

Weldmark #8 Premium Alumina Nozzle For HW-9,20,25 Torches

Weldmark #8 Premium Alumina Nozzle For HW-9,20,25 Torches

Weldmark TIG Short Back Cap For Hw-17, 18, 26 Tig Torches

Weldmark TIG Short Back Cap For Hw-17, 18, 26 Tig Torches

TIG Finger

TIG Finger

You don’t have to sacrifice your fingers for a pretty weld!

The Tig Finger® has become a welding industry standard, allowing welders to slide smoothly along hot metal,

It’s like having a prop in your pocket! And trust me… It’s durable…You’ll most likely lose it before you wear it out.

Don’t buy into imitations. Trust the original Tig Finger Heat Shield®.

**Tig Finger® Heat Shield is 100% Asbestos free and 100% Awesome, hand-made right here in the USA.

· Protects your finger from heat

· Allows you to make long weld passes

· Protects your welding gloves from becoming burned

· Durable and fits on your existing welding glove

· Perfect for the hobbyists or experienced welder

Best Welds 125 Amp Air Cooled TIG Torch Flex w/Valve Head

Best Welds 125 Amp Air Cooled TIG Torch Flex w/Valve Head

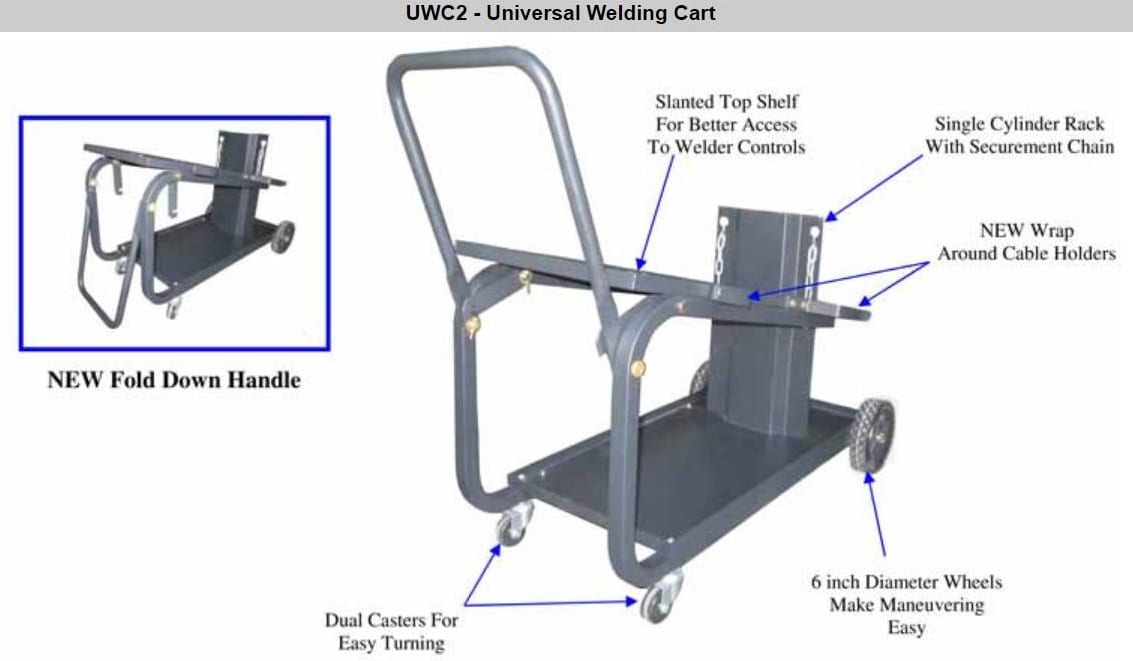

Metal Man Single Cylinder Universal Welding Cart

Metal Man Single Cylinder Universal Welding Cart

The Metal Man Universal Welding cart is designed to make maneuvering your welder easy. The single cylinder rack is capable of holding up to a 7-1/2 inch diameter, 80 lb cylinder and comes with a securement chain to hold the cylinder in place. The slanted top shelf accommodates most brands of welding equipment and places the welder controls at an easy to use angle. This great cart now comes with a NEW fold down handle. Use the handle to easily move your welding equipment into place then fold down the handle for easy access to welder controls. NEW wrap around cable holders help keep your cables organized.

SPECIFICATIONS:

- 110 lbs. capacity

- Dimensions: 32.3” X 18.3” X 29.7”

- Weight: 32 lbs.

- Steel construction with power coat finish

FEATURES:

Miller Syncrowave® 210 Multi-Process Welder

Miller Syncrowave® 210 Multi-Process Welder

WHAT’S INCLUDED:

- Syncrowave® 210

- 10 ft. (3 m) primary cord with MVP™ plugs for 120 V (219261) and 240 V (219258)

- 12 ft. (3.8 m) Weldcraft™ A-150 TIG torch with Dinse style connector

- 12 ft. (3.8 m) work cable with clamp and Dinse style connector

- 12 ft. (3.8 m) stick electrode holder with Dinse style connector

- RFCS-14 HD remote foot control

- Regulator/flow gauge and gas hose

- Quick Reference Guide

- 4-Pin to 14-pin connector

- Spoolmate™ 150 Series spool gun (#301 272)

Maxstar 161 STL 120-240 V, X-Case, Contractor Package

Maxstar 161 STL 120-240 V, X-Case, Contractor Package

WHAT’S INCLUDED:

- Maxstar® 161 STL

- 6.5 ft. (2 m.) primary cords for 120 V and 240 V

- 13 ft. (4 m.) stick electrode holder with 25 mm. Dinse-style connector

- 10 ft. (3 m.) work clamp with 25 mm. Dinse-stlye connector

- Adjustable handle/shoulder strap

- 12.5 ft. (3.8 m) Weldcraft™ A-150 TIG torch

- Regulator/flow gauge and gas hose

- AK2C accessory kit

- Protective Miller® X-Case™ (301429)

- Quick Reference Guide

Miller Multimatic 215 Multi-Process Welder & TIG Kit

Miller Multimatic 215 Multi-Process Welder & TIG Kit

Comes complete with

- Multimatic® 215

- Material thickness gauge #229895

- 5 ft (2 m) power cord and MVP™ adapter plugs for 120V and 240V

- 10 ft (3 m) MDX™-100 MIG gun

- 13 ft (4 m) cable electrode holder and 25 mm Dinse-style connector

- 10 ft (3 m) work cable and clamp

- Argon and AR/CO2 mix regulator/flow gauge with hose

- Spool of Hobart® .030 in (0.8 mm) solid wire

- Two contact tips for .030 in (0.8 mm) wire

- Quick Select™ drive roll for .024 in (0.6 mm) or .030/.035 in (0.8/0.9 mm) solid wire, and .030/.035 (0.8/0.9 mm) flux cored wire

- Hook-and-loop cord wraps

- TIG Kit for the Multimatic 215

CK Worldwide 2% Ceriated Tungsten

CK Worldwide 2% Ceriated Tungsten

7” 2% Ceriated Tungsten

These electrodes perform best in DC welding at low current settings but can be used proficiently in AC processes. With its excellent arc starts at low amperages, Ceriated tungsten has become popular in such applications as orbital tube and pipe fabricating, thin sheet metal work, and jobs involving small and delicate parts. Like thorium, it is best used to weld carbon steel, stainless steel, nickel alloys, and titanium, and in some cases it can replace 2 percent Thoriated electrodes. Ceriated tungsten has slightly different electrical characteristics than thorium, but most welders can’t tell the difference.

Using Ceriated electrodes at higher amperages is not recommended because higher amperages cause the oxides to migrate quickly to the heat at the tip, removing the oxide content and nullifying its process benefits.

CK Worldwide Lanthanated Tungsten 3/32″ X 7″

CK Worldwide Lanthanated Tungsten 3/32″ X 7″

3/32” X 7” 2% Lanthanated tungsten electrodes (AWS classification EWLa-2) contain a minimum of 97.80 percent tungsten and 1.30 percent to 1.70 percent lanthanum, or Lanthana, and are known as 1.5 percent Lanthanated. These electrodes have excellent arc starting, a low Burn off rate, good arc stability, and excellent re ignition characteristics—many of the same advantages as Ceriated electrodes. Lanthanated electrodes also share the conductivity characteristics of 2 percent Thoriated tungsten. In some cases, 1.5 percent Lanthanated can replace 2 percent Thoriated without having to make significant welding program changes.

Lanthanated tungsten electrodes are ideal if you want to optimize your welding capabilities. They work well on AC or DC electrode negative with a pointed end, or they can be balled for use with AC sine wave power sources. Lanthanated tungsten maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or AC from square wave power sources.

Unlike Thoriated tungsten, these electrodes are suitable for AC welding and, like Ceriated electrodes, allow the arc to be started and maintained at lower voltages. Compared with pure tungsten, the addition of 1.5 percent Lanthana increases the maximum current-carrying capacity by approximately 50 percent for a given electrode size.