Welding Supplies

Showing 181–200 of 448 resultsSorted by popularity

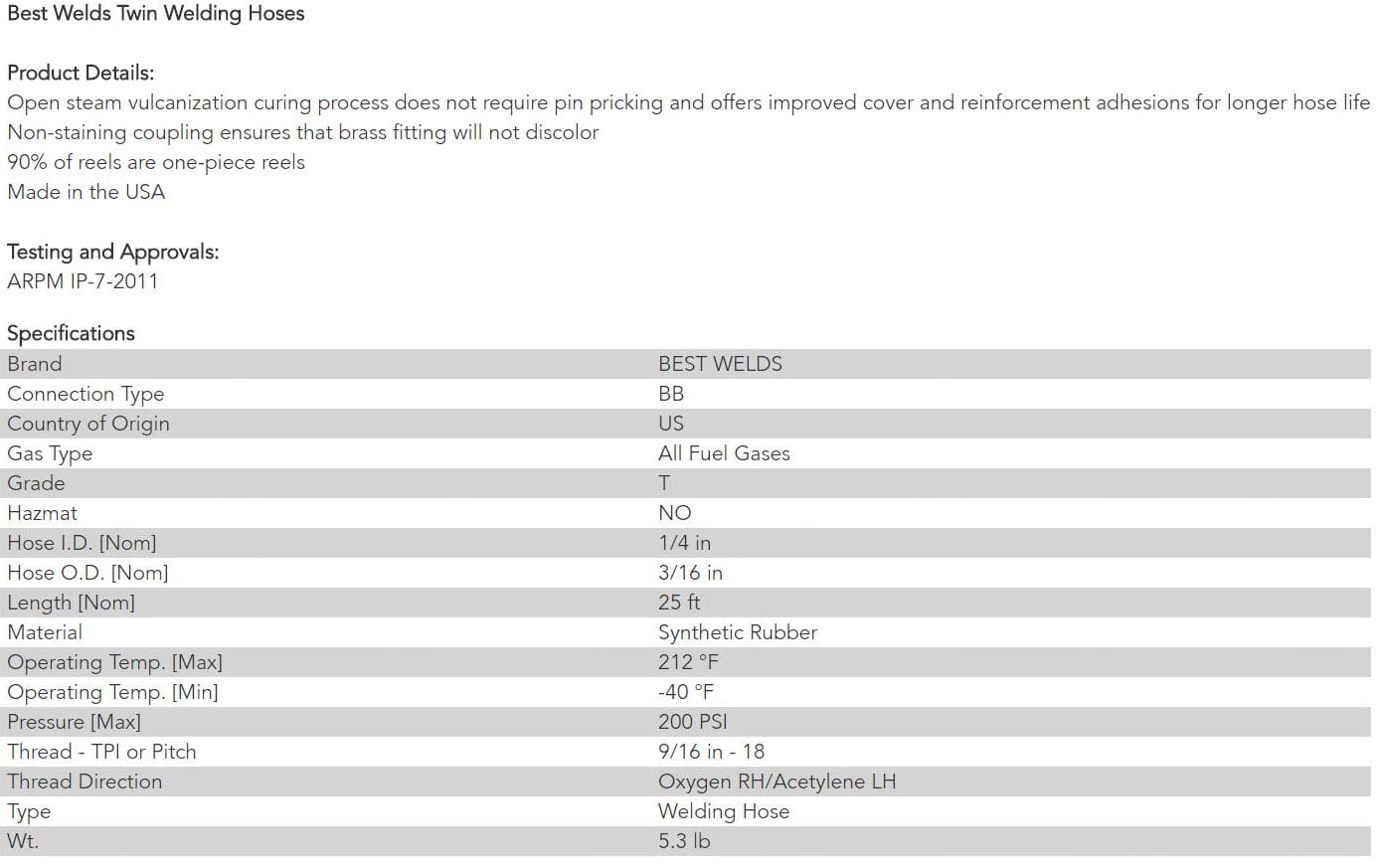

Hobart Deckmaster E6022 Mild Steel Stick Electrode

Hobart Deckmaster E6022 Mild Steel Stick Electrode

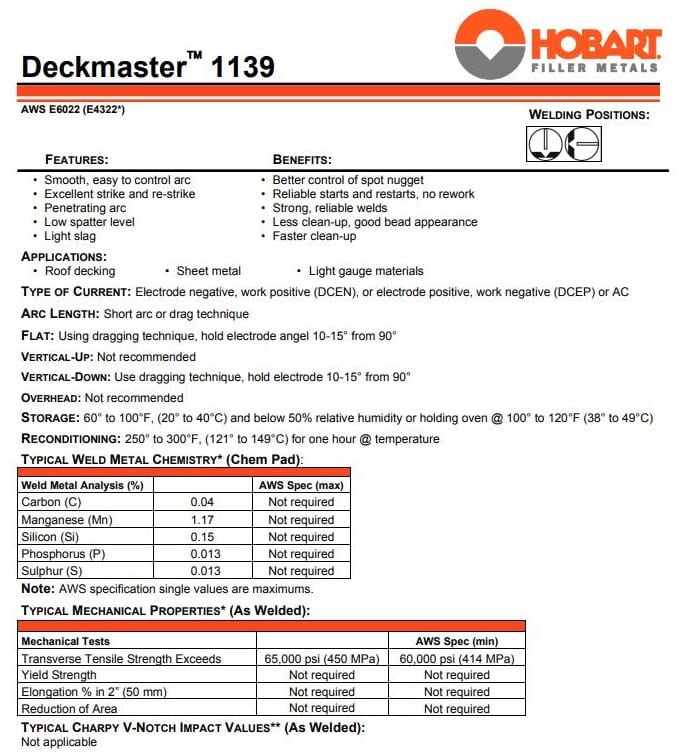

ESAB AtomArc 8018-CM Low Alloy Stick Electrode

ESAB AtomArc 8018-CM Low Alloy Stick Electrode

Weldmark 300 Amp Electrode Holder

Weldmark 300 Amp Electrode Holder

Weldmark Brand 300 amp stick electrode holder. Upper and lower tongs are made from a high copper alloy for maximum conductivity and strength. Top and bottom tip insulators are a molded fiberglass compound and will withstand intensive heat impact. Handles are molded from a durable glass filled nylon material with a good heat and impact resistance. Oval-point screw cable connection is standard on all models

Specifications:

· Amps: 300

· Electrode Cap.: 1/4 in

· Cable Cap.: 2/0

· Length: 10 inch

· Type: Medium Duty

Tweco 300 Amp Copper Ground Clamp

Tweco 300 Amp Copper Ground Clamp

Genuine Tweco® Professional Copper Ground Clamp with Ball-Point Cable Connection

Features

· Copper cast upper and lower jaws

· Insulated Spring

· Heavy Duty Spring providing the clamping force to the work surface

Specifications

· Material Composition: Copper Casting

· Amperage Capacity: 300

· Jaw Opening Depth: 4″

· Applications: Light Duty Metal Fabrication

· Overall Length: 8.5″

· Type Of Cable Connection: Ball-Point thru 3/0

· Style: Ground Device Clamp

· Jaw Opening: 1.5″

· Processes: SMAW, SAW, GMAW, FCAW, GTAW

Stoody 965-G Gas Shielded Semi-Automatic Hard Face Alloy Steel Tubular Wire .045 33# Spool

Stoody 965-G Gas Shielded Semi-Automatic Hard Face Alloy Steel Tubular Wire .045 33# Spool

Lincoln SuperArc LA-90 ER80S-D2/ER90S-D2/EA3K Low Alloy Steel MIG Wire .035 33# Spool

Lincoln SuperArc LA-90 ER80S-D2/ER90S-D2/EA3K Low Alloy Steel MIG Wire .035 33# Spool

CK Worldwide 2% Ceriated Tungsten

CK Worldwide 2% Ceriated Tungsten

7” 2% Ceriated Tungsten

These electrodes perform best in DC welding at low current settings but can be used proficiently in AC processes. With its excellent arc starts at low amperages, Ceriated tungsten has become popular in such applications as orbital tube and pipe fabricating, thin sheet metal work, and jobs involving small and delicate parts. Like thorium, it is best used to weld carbon steel, stainless steel, nickel alloys, and titanium, and in some cases it can replace 2 percent Thoriated electrodes. Ceriated tungsten has slightly different electrical characteristics than thorium, but most welders can’t tell the difference.

Using Ceriated electrodes at higher amperages is not recommended because higher amperages cause the oxides to migrate quickly to the heat at the tip, removing the oxide content and nullifying its process benefits.

CK Worldwide Lanthanated Tungsten 3/32″ X 7″

CK Worldwide Lanthanated Tungsten 3/32″ X 7″

3/32” X 7” 2% Lanthanated tungsten electrodes (AWS classification EWLa-2) contain a minimum of 97.80 percent tungsten and 1.30 percent to 1.70 percent lanthanum, or Lanthana, and are known as 1.5 percent Lanthanated. These electrodes have excellent arc starting, a low Burn off rate, good arc stability, and excellent re ignition characteristics—many of the same advantages as Ceriated electrodes. Lanthanated electrodes also share the conductivity characteristics of 2 percent Thoriated tungsten. In some cases, 1.5 percent Lanthanated can replace 2 percent Thoriated without having to make significant welding program changes.

Lanthanated tungsten electrodes are ideal if you want to optimize your welding capabilities. They work well on AC or DC electrode negative with a pointed end, or they can be balled for use with AC sine wave power sources. Lanthanated tungsten maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or AC from square wave power sources.

Unlike Thoriated tungsten, these electrodes are suitable for AC welding and, like Ceriated electrodes, allow the arc to be started and maintained at lower voltages. Compared with pure tungsten, the addition of 1.5 percent Lanthana increases the maximum current-carrying capacity by approximately 50 percent for a given electrode size.

CK Worldwide 1.5% Lanthanated Tungsten 1/8″ X 7″

CK Worldwide 1.5% Lanthanated Tungsten 1/8″ X 7″

3/32” X 7” Lanthanated tungsten electrodes (AWS classification EWLa-1.5) contain a minimum of 97.80 percent tungsten and 1.30 percent to 1.70 percent lanthanum, or Lanthana, and are known as 1.5 percent Lanthanated.

These electrodes have excellent arc starting, a low burn off rate, good arc stability, and excellent re ignition characteristics—many of the same advantages as Ceriated electrodes. Lanthanated electrodes also share the conductivity characteristics of 2 percent Thoriated tungsten. In some cases, 1.5 percent Lanthanated can replace 2 percent Thoriated without having to make significant welding program changes.

Lanthanated tungsten electrodes are ideal if you want to optimize your welding capabilities. They work well on AC or DC electrode negative with a pointed end, or they can be balled for use with AC sine wave power sources. Lanthanated tungsten maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or AC from square wave power sources.

Unlike Thoriated tungsten, these electrodes are suitable for AC welding and, like Ceriated electrodes, allow the arc to be started and maintained at lower voltages. Compared with pure tungsten, the addition of 1.5 percent Lanthana increases the maximum current-carrying capacity by approximately 50 percent for a given electrode size.

- AWS A5.12 EWLa-1.5

- ISO 6848 WL15

Weldmark TIG Collet 1/8″ For HW-17, 18, 26 Torches

Weldmark TIG Collet 1/8″ For HW-17, 18, 26 Torches

Weldmark TIG Collet 1/16″ For HW-17, 18, 26 Torches

Weldmark TIG Collet 1/16″ For HW-17, 18, 26 Torches

Weldmark #5 Gas Lens Alumina For HW-17,18,26 Torches

Weldmark #5 Gas Lens Alumina For HW-17,18,26 Torches

Weldmark TIG Long Back Cap For HW-20, HW-9 Tig Torches

Weldmark TIG Long Back Cap For HW-20, HW-9 Tig Torches

Thermal Dynamics 30-120 Amp Electrode For SL60/100 Plasma Torch

Thermal Dynamics 30-120 Amp Electrode For SL60/100 Plasma Torch

Thermal Dynamics Brand, Model 9-8215, 30 – 120 Amp Electrode

Compatible with Plasma Torch:

▪ CUTMASTER 52

▪ CUTMASTER 82

▪ CUTMASTER 102

▪ CUTMASTER 152

▪ SL60

▪ SL100

ESAB 15 Amp Cutting Tip PT-31/31XL Plasma Torch

ESAB 15 Amp Cutting Tip PT-31/31XL Plasma Torch

19 in stock

ESAB Brand ( L-Tec ), Model 19667 15 Amp Cutting Tip

Compatible with:

▪ PT-31

▪ PT-31XL

ESAB 30 Amp Cutting Tip for PT-31/31XL Plasma Torch

ESAB 30 Amp Cutting Tip for PT-31/31XL Plasma Torch

ESAB Brand, Model 18866 30 Amp Cutting Tip

Compatible with PT-31

Thermal Dynamics 100 Amp Air/Oxygen Tip For XT-301 Plasma Torch

Thermal Dynamics 100 Amp Air/Oxygen Tip For XT-301 Plasma Torch

Thermal Dynamic Brand, Model 35-1053 100 Amp Air/Oxygen Tip

Compatible with XT-301 plasma torch.

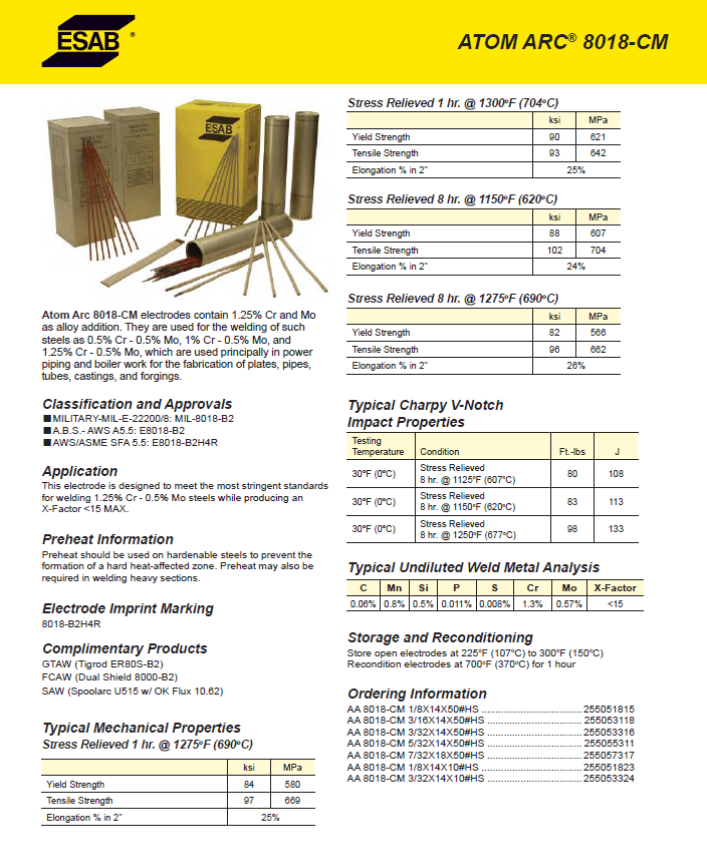

Best Welds 1/4″ X 25′ Twin Welding Hoses All Fuel Gases BB, T Grade

Best Welds 1/4″ X 25′ Twin Welding Hoses All Fuel Gases BB, T Grade