Description

1/4” shank with 1/4-20 female thread.

For quick change flap wheels

$6.00 – $60.00Price range: $6.00 through $60.00

For quick change flap wheels

| Package Size | 1, 10 |

|---|---|

| Brand | Pferd |

| Diameter | 1/4 |

| Type | Adapter |

Pferd 69954 Cut-Off Wheel

The Pferd Unversial PSF cut-off wheels are general purpose wheels providing fast cutting performance and good service life.

Specifications:

• Abrasive: Aluminum Oxide A

• Workpiece Materials: Steel

• Application: Cutting of sheet metal, sections and solid materials

• Diameter: 5 Inches

• Thickness: .045 Inches

• Arbor Hole/Thread Size: 7/8 A.H.

• Grit: 46

• Shape: Flat

• Max RPM: 12,200

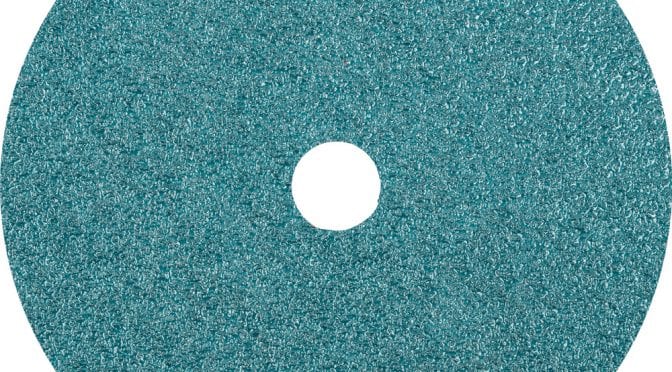

Zirconia Alumina Z – Standard (Plain Arbor Hole)

Designed for coarse grinding and high stock removal with an extended service life. Zirconia alumina is a high-performance abrasive which delivers best results on high-powered angle grinders at increase contact pressure.

Specifications:

| Diameter: | 7″ |

Pferd 42518 Quick Change Disc

COMBIDISC Abrasive Discs are great for grinding of steel and a variety of other metals and alloys. A wide range of abrasive grains, backing materials, and coatings ensure that there is a COMBIDISC for virtually any material or application.

COMBIDISC abrasive discs with aluminum oxide A grain are suitable for use on metals and other materials.

For general-purpose grinding from coarse to very fine, in diverse applications (industry, trades, DIY).

Specifications:

▪ Diameter: 3 Inch

▪ Grit: 80

▪ RPM Speed: 5,000 – 9,000

▪ Quick Change Hub: CDR – Roll On

▪ Abrasive: Aluminum Oxide A

Pferd 42520 Quick Change Disc

COMBIDISC Abrasive Discs are great for grinding of steel and a variety of other metals and alloys. A wide range of abrasive grains, backing materials, and coatings ensure that there is a COMBIDISC for virtually any material or application.

COMBIDISC abrasive discs with aluminum oxide A grain are suitable for use on metals and other materials.

For general-purpose grinding from coarse to very fine, in diverse applications (industry, trades, DIY).

Specifications:

▪ Diameter: 3 Inch

▪ Grit: 120

▪ RPM Speed: 5,000 – 9,000

▪ Quick Change Hub: CDR – Roll On

▪ Abrasive: Aluminum Oxide A

Reviews

There are no reviews yet.